Screen printing has two ways: one is fixed screen, moving substrates;The other is a fixed substrates, screen mobile, also calls the run printing, used for fabric printing.In printing, the printing substrates under the block;The latter at the time of printing, screen USES the dowel locating.

1.Blocking rules.The first section in this chapter introduces the silk-screen printing machine printing substrates support device, has introduced some substrates positioning method.Mainly introduces how to install below block gauge and some special substrates positioning method.

Substrates, when positioning can be used in plate making of the correct manuscript on the top of the printing machine, make the original image exactly the same as that of plate image location, so as to achieve the goal of positioning.If the manuscript is very scattered, according to the original position with transparent tape collage respectively the manuscript in the correct position of the substrates, its methods and pain version to the main point is the same.

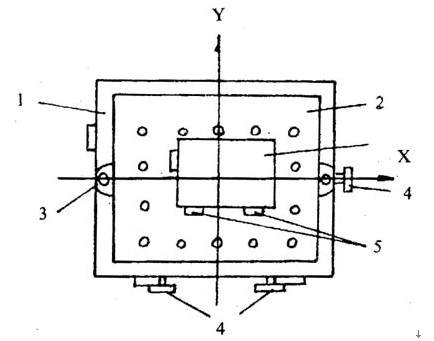

Substrates on printing platform, on either side of the substrates (given the substrates is a rectangle, it is in two parts of the long side and short side of a place), stick with substrates of the same thickness small pieces (metals, plastics, paper, etc.) as a gauge, thickness of rules also is a little thin substrates.But block gauge can't thick Yu Chengyin content, if the small piece of thicker than the substrates, printing will damage the screen and scraper, resulting in a printing quality.Semi-automatic, automatic screen printing machine, generally equipped with positioning device, such as automatic give assumed that a device, blocking rules (rules) device (e.g., telescopic, stationary and stick a piece of type gauge block), pin system, mold (nest) positioning device, etc.Semi-automatic, automatic screen printing press rules and manual printing method is basically the same.In matching color printing for version can turn adjusting screw to move when screen printing machine, make the print table placed blank (Yang) cross line and silk screen printing on the rules of graticule collocated, achieve the goal of positioning substrates.When adjustment, will make a cross rules first line Yang figure blank location on the print table according to the requirement, and then fixed on the framework of net mesh plate on printing on stage, then the fixed screw loosening, with the adjustment screw to adjust the printing machine in the horizontal and vertical position (X, y direction), until the screen plate with the cross on the blank lines coincide, fixed screw can be printed, as shown in figure 3-67.

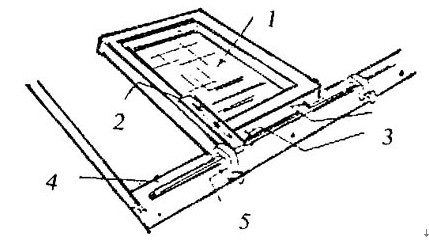

Figure 3-67 semi-automatic screen printing press set rules

L - printing table 2 - chuck table 3-4-5 - adjustment screw fixed screw gauge block

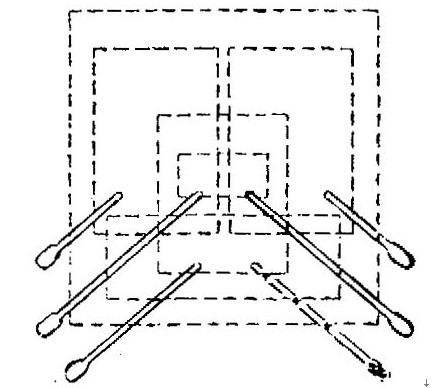

FIG. 3-68 adjustable gauge block

Block now many substrates for edge tidy.Figure 3-68 for adjustable block gauge, commonly used in circuit board printing machine.The bar gauge on the ink pad, can slide along the groove, for different size, different angles and at the same time place more substrates configuration required piece of rules.

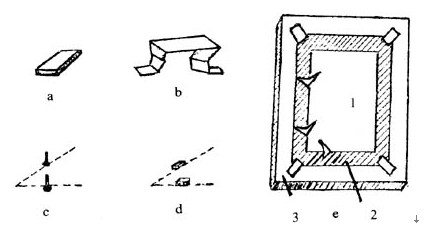

Block gauge should vary with substrates, in the form of figure 3-69 - a as the chip block gauge, used for thin sheet substrates, adopt a little thin cardboard or plastic production than substrates, and adhesive on the ink pad with it;B for origami block gauge, have certain of the opening of the play, to adapt to the thicker substrates;C for pile (or nail) block gauge, d for cube block gauge, can be used for thick substrates;E is a Zhang Pingting fixed on the ink pad of paper or plastic, draw the location of the substrates in the appropriate position, and located in three each time a v-shaped sheet as gauge block, folded along the line of position, make the sheet is on the top of the substrates, visual and touch simultaneously when feeding, more convenient, loose also help substrates and web version of the separation.

FIG. 3-69 various forms of block now

L - 2 - positioning substrates piece 3 - printing machines

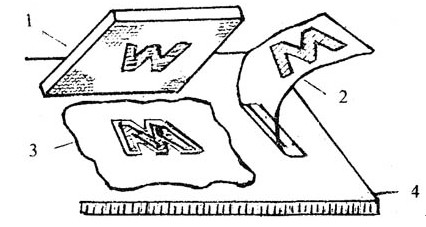

FIG. 3-70 coated method

1 - plate 2 - transparent film 3 and 4 substrates a printing machine

When faced with irregular shape or soft substrates, appropriate is used as shown in figure 3-70 coated positioning method, namely a first transparent film on the ink pad, and printed on the image, then buy substrates in a factory, which can directly identify the position relationship between image and substrates.

Figure 3-71 for some of the pin set of devices, precision printing machine with the characteristics of a set of accurate and reliable and high precision positioning operation procedure is as follows: a.The substrates (or Yang figure film) on the positioning hole to the ink pad positioning pin.B.Will a painted screen frame range of transparent film on the ink pad on the control panel of shift stamp-pad stamp-pad ink to printing machine on the printing position of ZhuangYin version within the screen bracket, and a preliminary adjustment box, to make it with a box on film sets, and then fully fixed net frame, testing-run, imprinted on the film.C. would use the stage three fine adjustment screw, adjust the ink pad accurately, made the substrates on the control panel (film) (or positive) with the mark on the film will be completely accurate, and then remove the film, erase the imprinting, formally began printing.

FIG. 3-71 printing pin system

Printing pin set of system used in precision screen printing in advance unified punching film, metal, glass as material of PCB, meter scale and dial printing quality.

When the ink pad for transparent mesa and substrates is pervious to light quality, by the light of, can intuitively substrates and corresponding tag stamp pad will be allowed, do not need to make positioning device.

2.Run version of positioning.For soft, easy to deformation and porous substrates, such as fabric, etc., are difficult to gauge with block positioning.Therefore, should be the number of substrates with fixed on the strip stamp-pad stamp-pad ink paste method.Printing, the mobile version of the print, one by one for each screen printing position as shown in figure 3-72, the net space by guide rail inside, the positioning pin item on the net shape of contact patches on the space depend on the guide rail clips, screen orientation.

FIG. 3-72 run version of positioning

L - plate piece of 3-2 - contact adjustable locating pin 4-5 - wing clip of the rails